the

CHAOTIC FIRE

AVAILABLE NOW ►

Truly Unique

end grain

CUTTING BOARDS

Individually

HANDCRAFTED

PRECISION works of ART.

The most beautiful

CUTTING BOARDS

you've ever seen.

BOARDS

Our unique end grain cutting boards. Or as we like to put it... our functional works of art.

AVAILABLE

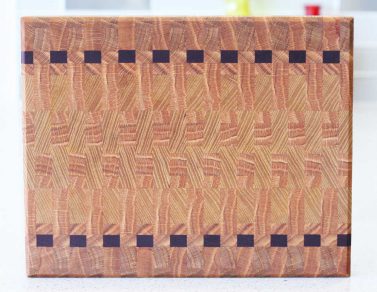

Waves of Oak

Ash, Available, Maple, Padauk, Red Oak

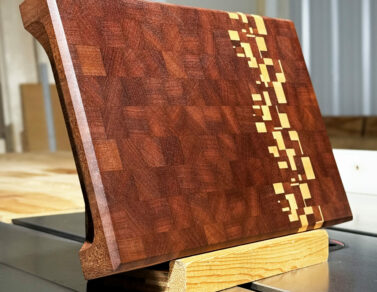

Fracture

Available, Chaos, Maple, Sapele

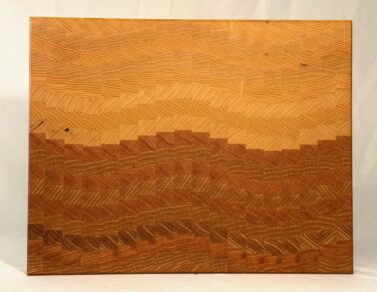

Desert Wave

Ash, Available, Red Oak

Cherry Wave

Ash, Available, Cherry, Maple, Purple Heart

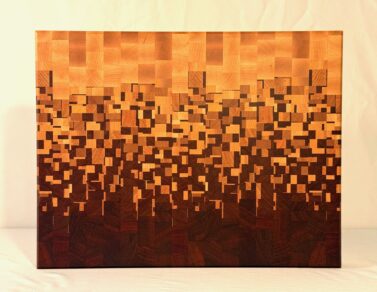

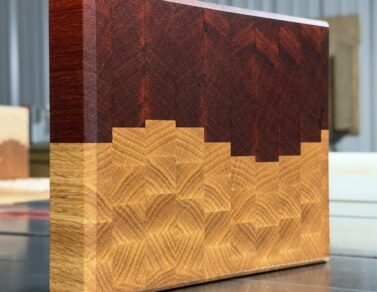

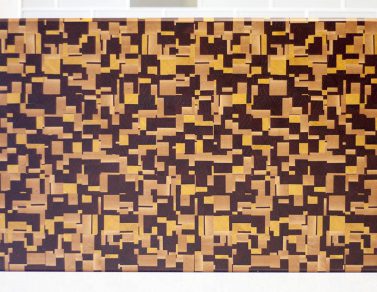

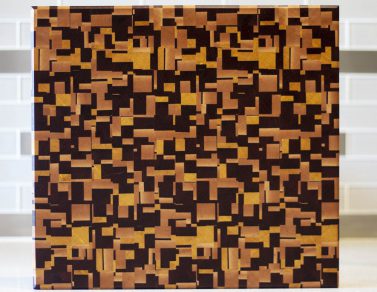

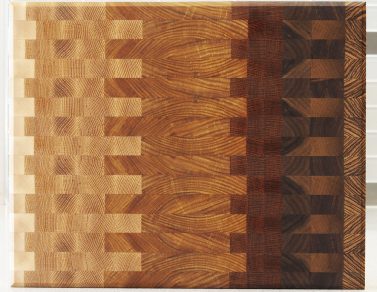

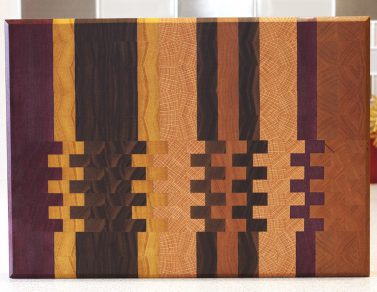

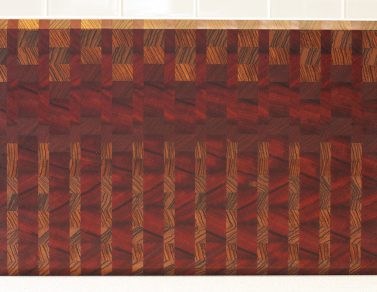

Chaotic Fire

Ash, Available, Chaos, Maple, Padauk, Sapele

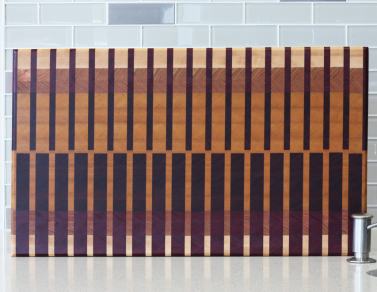

Purple Pixel

Ash, Available, Cherry, Maple, Purple Heart

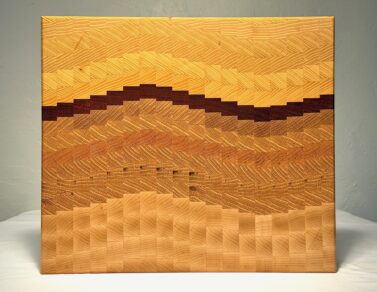

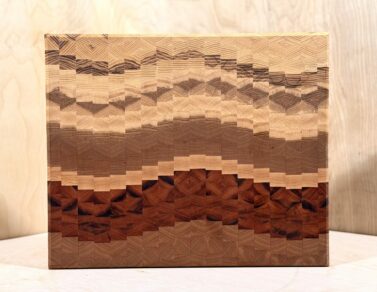

Autumn Wave

Available, Padauk, Red Oak

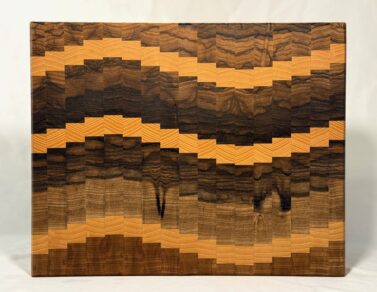

Mosaic Sea

Available, Black Limba, Chaos, Padauk, Zebrawood

Golden Road

Ash, Available, Black Limba

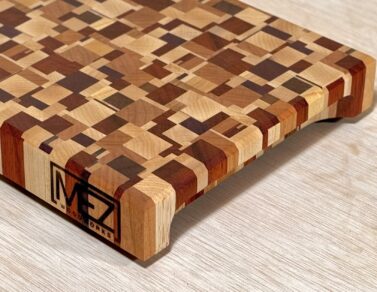

Chaotic

Ash, Available, Chaos, Cherry, Maple, Padauk, Purple Heart, Red Oak, Sapele

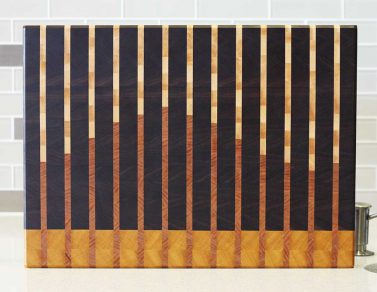

The Purple Heart Wave

Available, Maple, Purple Heart, Red Oak

SOLD OUT

Unwavering Cherry

Cherry, Maple, Purple Heart, Sold

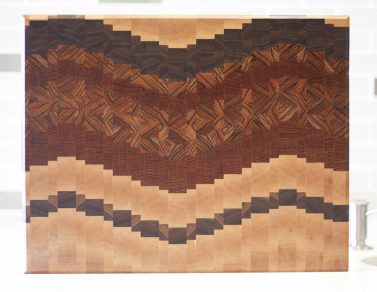

Mirage

Ash, Cherry, Maple, Sold, Tigerwood

L’espion – The Spy

Black Limba, Canarywood, Maple, Red Oak, Sold, Zebrawood

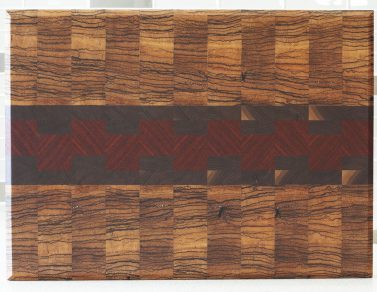

Dark Ethereal

Black Limba, Padauk, Sold, Zebrawood

Cryptic

Black Limba, Canarywood, Maple, Sapele, Sold, Zebrawood

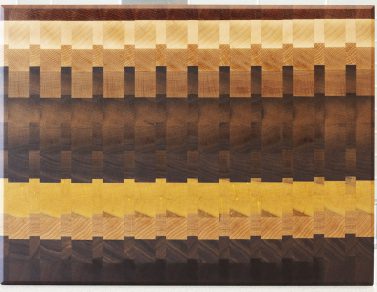

Big Chaos I

Chaos, Maple, Sapele, Sold, Yellow Heart

Big Chaos II

Chaos, Maple, Sapele, Sold, Yellow Heart

Exotic Safari

Maple, Sapele, Sold, Walnut, Zebrawood

Parallel Padauk I

Cherry, Padauk, Sold, Walnut, Zebrawood

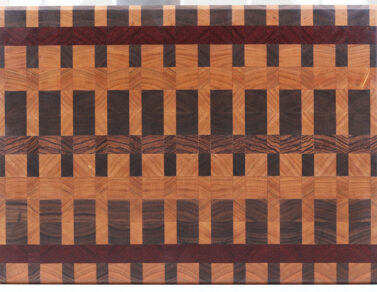

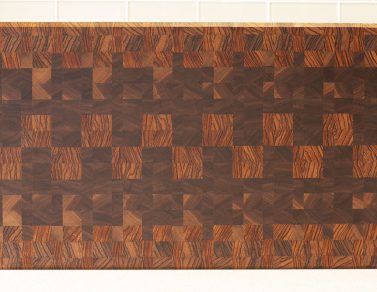

Walnut Weave

Maple, Sapele, Sold, Walnut, Zebrawood

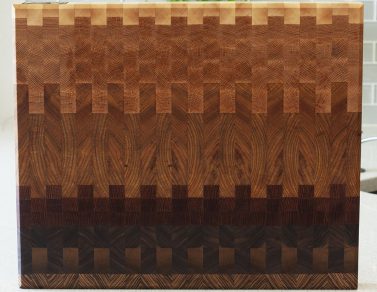

Fade To Black I

Cherry, Maple, Red Oak, Sapele, Sold, Walnut

Fade To Black II

Cherry, Maple, Red Oak, Sapele, Sold, Walnut

Canary Mine I

Canarywood, Lacewood, Maple, Red Oak, Sold, Walnut, Zebrawood

Alter Ego II

Canarywood, Maple, Red Oak, Sapele, Sold, Walnut, Yellow Heart

Canary Mine II

Canarywood, Lacewood, Maple, Red Oak, Sold, Walnut, Zebrawood

Crossing Yellow I

Cherry, Lacewood, Maple, Red Oak, Sapele, Sold, Walnut, Yellow Heart

Next Level I

Padauk, Sold, Walnut, Yellow Heart

Zebra Safari I

Padauk, Sold, Walnut, Zebrawood

Zebra Lace Wave

Lacewood, Maple, Sold, Walnut, Zebrawood

The Zebrawood Flip

Maple, Padauk, Purple Heart, Sold, Yellow Heart, Zebrawood

Color Tune I

Cherry, Purple Heart, Red Oak, Sold, Walnut, Yellow Heart

Shift I

Maple, Padauk, Sold

Hail Caesar

Cherry, Maple, Padauk, Purple Heart, Sold, Yellow Heart

Waves of Walnut

Cherry, Maple, Padauk, Purple Heart, Sold, Yellow Heart

Small Oak Big Heart

Ash, Purple Heart, Red Oak, Sold

Wave of Cherry

Cherry, Maple, Sold, Walnut, Yellow Heart

Fire and Tiger

Padauk, Sold, Zebrawood

New Tradition

Sold, Walnut, Zebrawood

THE GUARANTEE

Each and every unique end grain cutting board we make is guaranteed for life. If you experience any problems with your Mez Woodworks cutting board, contact us and we'll make it right.

Caleb Calloway & Sean Gomez, Mez WoodworksBOARD CARE

Mez Woodworks unique end grain cutting boards can last a lifetime, and even longer. They are supremely durable and naturally beautiful, as well as being an art piece for the kitchen. However, like all wooden cutting boards, they can be susceptible to warping and cracking when not properly cared for.

Wood Armor

Mineral Oil

Mineral oil is food-safe, doesn’t go rancid, and helps prevent water from seeping down into the wood grain. Mineral oil also prevents your prized cutting board from drying out and cracking.

Applying Mineral Oil

Using a soft cloth, spread two quarter sized amounts of mineral oil on each side of the cutting board, let the oil soak in for at least 5 minutes. Wipe off excess if desired. You can reuse your cloth each day if you’d like to minimize waste. You can use your cutting board every day, just be sure to clean and oil your board after each use.

Wood Armor - Even Better!

Wood Armor contains a special blend of mineral oil and organic beeswax. This adds another layer of protection for your prized end grain cutting board. You can also use Wood Armor on any unfinished wood product you use in the kitchen or at the dinner table!

Fruits and Vegetables

After cutting fruits or vegetables, just wipe dry and apply mineral oil as normal.

Raw Meat

After use, wash with a small amount of warm water and a very small amount of dish soap. Rinse and dry the board, then, immediately apply mineral oil as normal.

Serrated Knives

Avoid using serrated knives on the cutting board, they have a tendency to saw away the surface.

Water

Do not let your cutting board sit in moisture for an extended amount of time.

Dry Storage

Store your Mez Woodworks cutting board in a dry place.

THE PROCESS

Unique end grain cutting boards require an exacting, repeatable process.

- 01

Design

The design is the most important part of the process. Without a good design, nothing else works.

- 02

Wood Selection

The most beautiful cutting boards require very meticulous selection when it comes to the woods used.

- 03

Wood Preparation

Every piece of hardwood used goes through a rigorous preparation process.

- 04

Precision Cutting

Precision tools and techniques are used to make each cut perfect.

- 05

Assembly

Every cutting board is assembled with great care. Gluing requires 24 hour drying time and some boards require three or more gluing sessions.

- 06

Finishing

Beveling, cutting hand holds, sanding, oiling, waxing, attaching feet. This step requires the most hands-on time, but is also the most rewarding.

- 07

Delivery

Now that your unique end grain cutting board is finished, we ship it directly to you and provide tracking information for your convenience.

Shows & Festivals

Want to see our unique end grain cutting boards in person? Visit us at one of these exhibits.

THE COMPANY

Unique end grain cutting boards are our business.

WE ARE UNIQUE

Want something unique and different, something that will last a lifetime, but very few people have? Our unique end grain cutting boards are what you are looking for.

WE ARE CONSISTENT

Every design choice matters. Every wood selection matters. Every detail matters. Every board, every time. No exceptions.

WE CARE

We care about every aspect of our boards and service. We take this very seriously. We know you want the best and we want to deliver.

THE TEAM

Just the two of us.

Mez Woodworks is a father-son team.

When I started Mez Woodworks, it was just me, Sean Gomez. Now, I’ve brought my son Caleb into the business. Today, Caleb is becoming a master woodworker as we learn every day, together.

Our Mission: To make the most beautiful and unique end grain cutting boards you’ve ever seen.

You can buy yourself a nice cutting board just about anywhere. We wanted to make something much better than “nice”. Something that is so beautiful, so artistic, and yet supremely durable that nothing could compare.

Doing this means spending real time on each cutting board. At least 15 hands-on hours over the course of four days go into each and every end grain cutting board we make. See more about the process here.

Above all, though, it’s a labor of love. We’ve thoroughly enjoyed bringing these works of art to life, and we hope you too can enjoy one of these amazing cutting boards for yourself!

Far and away the best prize that life has to offer is the chance to work hard at work worth doing.

Theodore RooseveltWHY OUR BOARDS

With unique end grain cutting boards, there is more than meets the eye.

Durability

End grain cutting boards are, by their very nature very durable. Each knife cut goes between the wood grain, rather than cutting through them.

Self Healing

Because knife cuts go between the wood grain, the wood grain can come back together much more easily. Edge grain cutting boards can’t do that.

Antibacterial

Against commonly accepted beliefs, end grain cutting boards are much less susceptible to bacteria growth and in fact inhibit and kill bacteria.

Knives Stay Sharper

Because you are cutting between the wood grains, your knives are cutting on a naturally forgiving surface, keeping your knives sharper.

Contact

info@mezwoodworks.com

Address

Mez Woodworks

3645 NW 70th St

Oklahoma City, OK 73116

Telephone

405-792-4300